Jerome Dubois, 6 River Systems co-CEO and co-founder

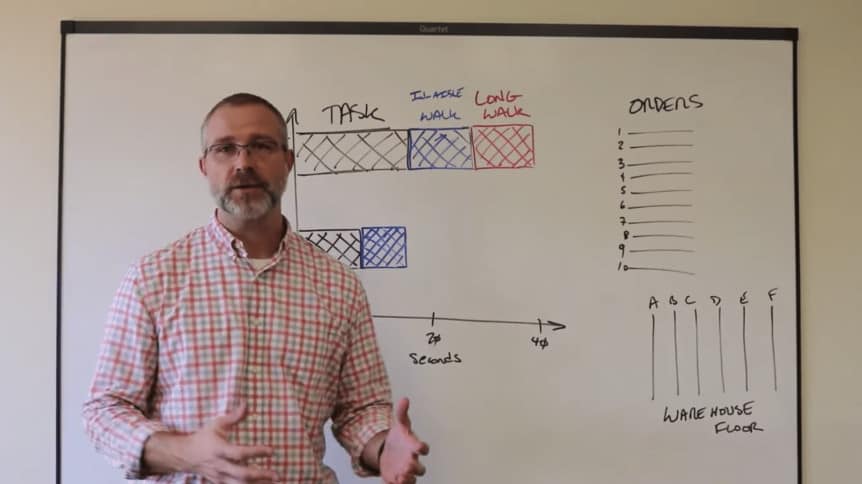

There are lots of warehouse robotics companies on the market now, all trying to make fulfillment faster and better. Most of their solutions fixate on eliminating long walks — the time associates rack up walking around to and from the picking area. From an automation perspective, that’s a fine approach, but a narrow one. There are more inefficiencies lurking in between the aisles of a warehouse that go beyond just non-value-added walking.

At 6 River Systems, we use software in addition to our robot Chuck to generate performance improvements for your associates and our equipment. Here’s how:

Reducing in-aisle steps

In warehouses with manual carts, pickers spend a lot of time walking in between aisles in a mostly random fashion. At first glance, it may make sense, for example, to pick in FIFO (first in, first out) order, taking the first four pick lists from the stack at the wave prep desk. This leads operators to pick items for orders 1 through 4 in chronological order, often one order at a time, and possibly revisiting the same aisle or the very same location more than once. But what if orders 1,2, 8, and 10 have picks in the same aisle or even the same location? And what if the operator knew how many total items to pick for their cart at the location?

That’s exactly what our software does. We call it smart work allocation. We apply advanced algorithms and AI in our cloud-based servers to actually reduce the number of steps that an operator takes and aisles they visit. Our software decides, in real-time, which picks are the best for your pickers while they’re in-aisle, creating more dense and productive routes than they’d get using manual carts.

Doing tasks more efficiently

Once pickers get in-aisle, they run into another efficiency problem: picking the right items into the right totes. In an entirely manual situation, pickers are juggling a lot. They are rarely hands-free because they need to handle an RF gun, a paper pick list and push a manual cart. They need to identify which bin the pick is located in, and they need to make sure they’re picking the right item into the right tote.

With our software, the robot stops exactly where the pick is located, displays a picture of the item on a screen and lights up on the left or right, indicating which side of the aisle the pick is located in. The software also powers the put-to-light technology, which shows pickers which totes to place items into.

The 6 River Systems software enables us to deliver huge value to customers. They see 2X to 3X gains in pick rates, less walking in aisle, more accurate picks and happier associates. For more information on 6 River Systems technology, visit our website at 6river.com.

For a visual take on this, check out my latest whiteboard video session:

Related: How collaborative robotics deliver better value than goods-to-person